Premium A2 (304) and A4 (316) stainless steel Small Eye bolt. Available in metric coarse threads and select UNC/BSW on request. Mill Test Certificates (MTC), strict dimensional tolerances, and fast dispatch from ready stock.

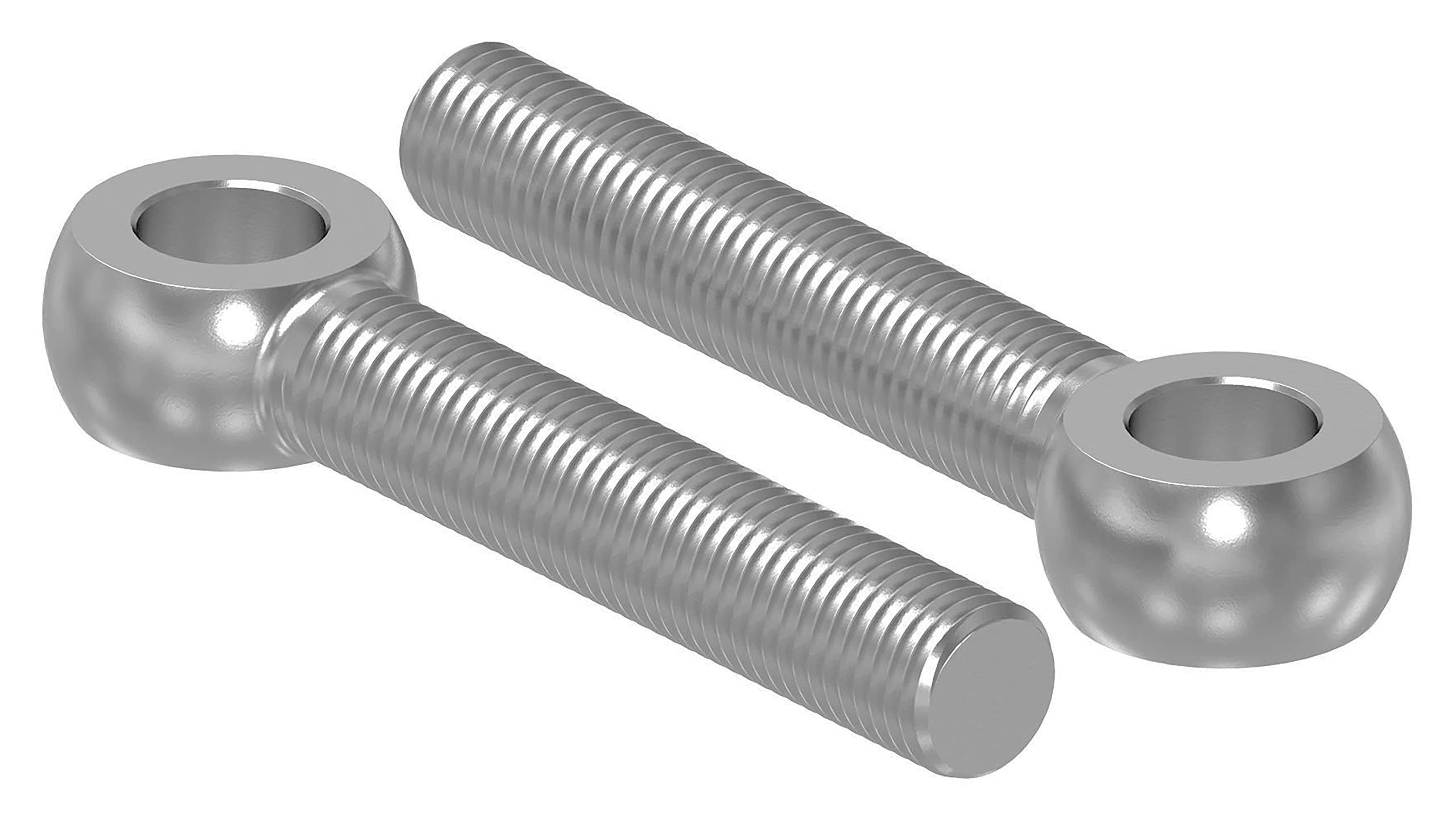

Stainless Steel Small Eye Bolt

Key Specifications

Choosing the Right Stainless Steel Small Eye Bolt

Choosing the Right Small Eye Bolt

1) What is a “small” eye bolt & when to use it?

A small eye bolt is a compact fastener with a threaded shank and an eye (ring) at the end, typically in smaller sizes like M4, M5, M6, M8 etc.

Use a small eye bolt when you need a light-duty attachment or guide point, such as:

Fixing small brackets, chains, and cables

Hanging light fixtures, signs, trays, and panels

Guiding wires, ropes, and tensioners

Decorative or architectural uses on railings, furniture, or display systems

For heavy lifting or overhead hoisting, always move to rated lifting eye bolts (e.g. DIN 580) – small hardware eye bolts are usually not certified for lifting.

2) Environment & corrosion – A2 vs A4 for small eye bolts

Choose the stainless grade based on where the eye bolt will be installed:

A2 (304) small eye bolts

Use in indoor and general outdoor conditions

For light fixtures, cable guides, small brackets, signage, display hardware, and general plant use

A4 (316) small eye bolts

Use in marine, coastal, poolside, or chemical areas

For boat fittings, seafront railings, pool equipment, wash-down areas, and corrosive atmospheres

Match materials:

A2 eye bolt with A2 washers/nuts or A2 hardware

A4 eye bolt with A4 washers/nuts or A4 hardware

This keeps the entire assembly at a similar corrosion resistance level.

3) Eye bolt type – what are you screwing into?

Small eye bolts come in two main shank types:

Machine thread eye bolts (metric thread: M4, M5, M6, M8…)

Straight machine thread for metal or pre-threaded components

Use when:

You have a tapped hole in metal

You pass through a plate and secure with a nut + washer

Wood / screw eye bolts (wood screw or self-tapping type)

Coarse, sharp, screw-like thread for timber, plugs, or softer materials

Use when:

You screw directly into wood, plugs, or plastic anchors

You are hanging or guiding light items from timber or masonry (with wall plugs)

Simple rule:

Fixing into metal or through a plate → Machine thread eye bolt + nut/washer.

Fixing into wood / wall plugs → Screw / wood-type eye bolt.

4) Load level & size selection (light duty vs stronger small sizes)

Even for “small” eye bolts, load matters:

Very light duty (tags, small chains, light signs, curtain wires)

Small sizes like M4 / M5 or equivalent screw-eye sizes

Anchored into appropriate plugs or timber

Medium duty (light plant hardware, small trays, cable clusters, small turnbuckles)

Sizes like M6 / M8

Through-bolted with nut & washer, or into properly sized metal/tapped plates

When in doubt, choose:

A slightly larger size and

A better fixing method (through-bolt + nut/washer) rather than a tiny screw eye in weak material.

Remember: small hardware eye bolts are not lifting points unless they are part of a rated lifting system.

Mechanical Properties (Guide)

Mechanical Properties (Guide) – Small Stainless Eye Bolts

For “small” eye bolts used as hardware and light fixings, the main concern is practical load capacity of the fixing rather than formal lifting ratings. Many small eye bolts are not property-class marked and are not certified for lifting.

A2 (304) Small Eye Bolts

Material: A2 (304) stainless steel

Typical use:

Light-duty suspension, guiding, and attachment points in non-marine environments

Interior and normal exterior usage where rust-staining must be avoided

Depending on the manufacturer, they may or may not be marked with a property class.

When property classes are given (e.g., A2-50, A2-70), they follow the usual stainless fastener strength rules.

A4 (316) Small Eye Bolts

Material: A4 (316) stainless steel

Typical use:

Marine, coastal, poolside, or chemical areas

Small fittings on boats, docks, railings, ladders, pool equipment, and process areas

Again, they may not always be explicitly property-class marked, but the material has higher corrosion resistance than A2.

What We Do

Our Legacy & Mission

Frequently Asked Questions

A small eye bolt is a compact eye-shaped fastener with a threaded shank (often M4, M5, M6, M8, etc.) used for light to medium-duty attachment points – for cables, chains, signs, fixtures, and small hardware.

Generally no.

Most small eye bolts (hardware type) are for fixing, hanging, and guiding only – not for overhead lifting.

For lifting people or heavy loads, always use a rated lifting eye bolt (e.g. DIN 580) with a declared Working Load Limit (WLL).

w

Not directly with just the bolt. You need a suitable anchor system:

For screw/wood eye bolts → use a correctly sized wall plug or chemical anchor sleeve.

For machine-thread eye bolts → use a mechanical anchor or chemical anchor with internal thread and then screw the eye bolt into that.

Always match the anchor capacity to the load and check the base material condition.

Closed eye (fully closed or welded):

Safer and more secure for chains, shackles, and permanent links.

Reduces risk of the connection jumping out.

Open eye:

Easier to hook/unhook items.

Only suitable for very light, non-critical uses.

For anything more than decorative/light-duty → choose closed eye.

contact us

Partner with us for precision, quality, and reliability. Reach out and let's start building together.