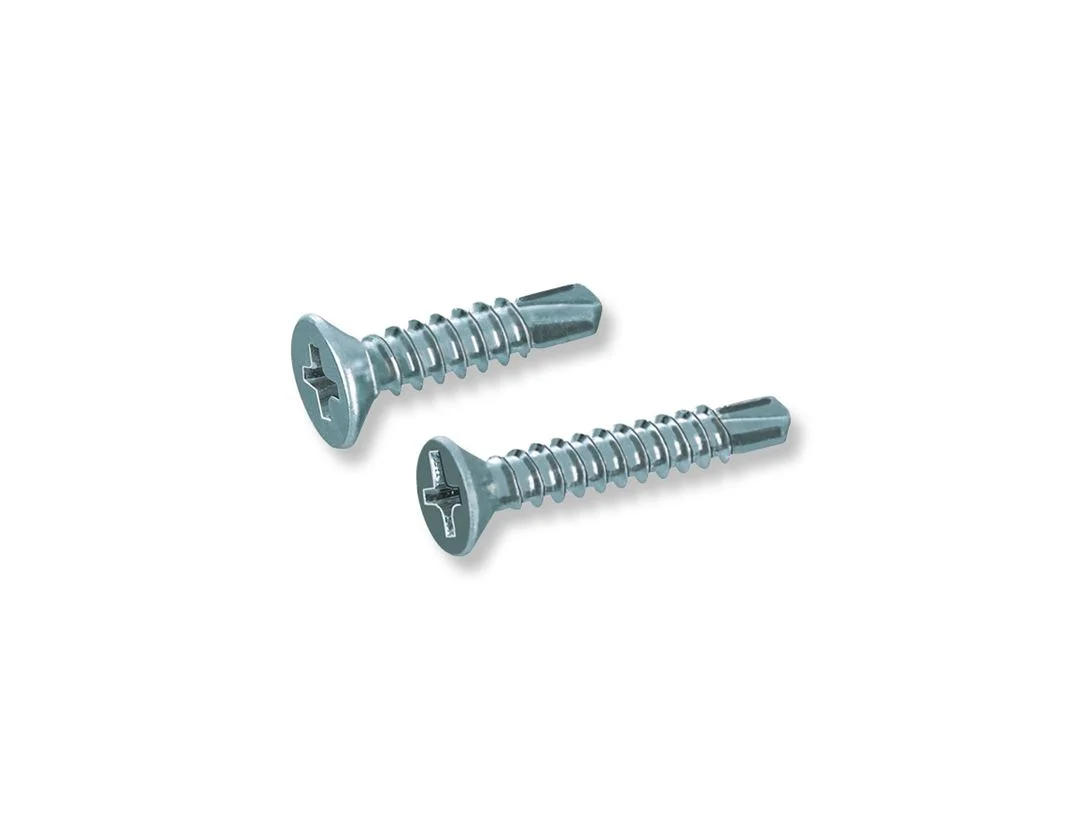

Premium A2 (304) and A4 (316) stainless steel csk head self drilling screw. Available in metric coarse threads and select UNC/BSW on request. Mill Test Certificates (MTC), strict dimensional tolerances, and fast dispatch from ready stock.

Stainless Steel Csk Head Self Drilling Screw

Key Specifications

Choosing the Right Stainless Steel Csk Head Self Drilling Screw

Choosing the Right SS CSK Head Self-Drilling Screw (Guide)

for stainless steel countersunk (CSK) head self-drilling / Tek screws

1. What is an SS CSK Head Self-Drilling Screw?

An SS CSK head self-drilling screw is:

CSK (countersunk) head → flat, conical head that sits flush with the surface after countersinking

Self-drilling tip → drill-bit shaped point that drills its own hole in thin metal

Self-tapping machine thread → forms its own mating thread in the base metal

Made fully or partially in stainless steel (head/cap, body or both)

It is used when you want to drill, tap and fasten in a single operation, with the head flush to the surface (no projection).

Typical drive: Phillips / Pozi / Torx CSK head.

2. Where & When to Use CSK Self-Drilling Screws

Use SS CSK head self-drilling screws when:

You are fixing sheet metal to sheet metal or to light sections, and

You want the head to be flush or slightly below the surface, e.g.:

Control panel fronts

Covers and access plates that must be smooth

Stainless facias / trims / door plates

Hinges or hardware on sheet where snag-free finish is needed

Avoid them when:

Sheet is very thin and countersinking will weaken it or cause “knife-through”

You don’t care about flush finish → pan or hex head is simpler & stronger on thin sheet

Joint is structural / high load → use bolts / anchors instead.

3. Important: What Does “Stainless” Mean Here?

For self-drilling, the tip must be very hard. Pure A2/A4 stainless is relatively soft, so in practice you usually get:

Carbon-steel self-drilling core + stainless CSK head/cap

Drill tip & shank: hardened carbon steel (for drilling)

Head/cap: stainless steel for appearance & corrosion resistance

Bi-metal / full stainless body with hardened drill tip

Body: A2 (304) or A4 (316) stainless

Drill tip: hardened carbon steel piece welded/bonded, or specially treated point

When you see “SS CSK self-drilling screw”, always clarify internally or with supplier:

Full SS/bi-metal, or carbon-steel driller with SS CSK head/cap?

This affects drilling capacity, corrosion behaviour and cost.

4. Environment & Stainless Grade

a) Normal indoor / mild outdoor / general industrial

You can use:

Carbon-steel self-drilling screws with good coating (zinc/Ruspert) and SS CSK head/cap, or

A2 (304) bi-metal CSK self-drillers for thin steel/aluminium.

Suitable for:

Electrical panels, machine covers

Indoor cabinets, general fabrication.

b) Coastal / marine / chemical / aggressive

Prefer:

Bi-metal or A4 (316) body CSK self-drilling screws

Stainless CSK head + high-grade coating on any carbon-steel portion

Full A4 contact surfaces where long life and appearance are critical.

Use these for:

Outdoor stainless facades

Food/pharma, chemical plant panels

Coastal and marine installations.

c) Low-cost, dry indoor

Standard carbon-steel drillers with plating may be acceptable if customer doesn’t truly need stainless exposed surfaces.

Mechanical Properties (Guide)

Mechanical Properties (Guide)

Exact values are product-specific, but you can think in two categories:

A. Carbon-Steel Self-Drilling Core + SS CSK Head/Cap

Core: case-hardened carbon steel

Tensile strength: typically around 900–1200 MPa

Shear strength: high – suitable for normal panel/bracket applications

Drill tip hardness: high enough to drill rated thickness of steel

Corrosion behaviour:

Head & visible area: good, due to stainless cap/head

Shank in overlap zone: protected by plating; good for normal environments, but not as corrosion-proof as full A4 in severe coastal/chemical conditions.

B. Bi-Metal / Full Stainless Body with Hardened Drill Tip

Body: A2 (304) or A4 (316) stainless

Typical tensile strength: similar to A2-70 / A4-70 (~700 MPa tensile)

Drill tip: hardened carbon-steel piece or specially treated stainless

Corrosion behaviour:

For A4 (316) versions → excellent in marine/coastal/chemical atmospheres.

Body & head maintain appearance and integrity much longer than coated carbon-steel in harsh environments.

In CSK self-drilling applications, failure is usually governed by sheet bearing / countersink tear-out / corrosion at sheet interface, not pure shank tensile failure.

11. Quick Selection Cheat Sheet (Floor Use)

Surface requirement

Need flush, snag-free finish → CSK head self-drilling

Head can sit on top → pan or hex head (stronger on thin sheet).

Environment

Normal industrial / indoor / mild outdoor → carbon-steel core with SS CSK head OR A2 bi-metal

Coastal / chemical → A4 bi-metal CSK self-drilling where possible.

Material & thickness

Thin sheet + thin base within rated thickness → self-drilling OK

Too thick/hard → pre-drill or use bolts.

Diameter

Nameplates/light covers: 3.5–4.2 mm

General sheet panels/hinges: 4.2–4.8 mm

Heavier plate/bracket: 5.5–6.3 mm

Installation tips

Correct bit, straight alignment

Drill, then slow down when thread engages

Tighten until flush – don’t over-pull the countersink.

What We Do

Our Legacy & Mission

Frequently Asked Questions

It is a stainless steel countersunk (flat) head screw with a drill-shaped tip that can drill, tap, and fasten in one operation into thin metal. The CSK head sits flush with the surface after countersinking.

You’ll typically find them in:

Control panels and front plates

Electrical / electronic covers and access plates

Stainless trims, fascias, claddings

Hinges, handles, and hardware on sheet metal where a flat, snag-free surface is required

Anywhere the surface needs to be smooth and visually clean.

Choose CSK when:

You want the screw head to be flush or slightly below the surface

There should be no projection (for aesthetics, safety or sliding parts)

Choose pan/hex head when:

The sheet is thin and countersinking might weaken it

You don’t mind a visible head and want simpler drilling (no countersink step)

You want more bearing area on very thin sheet (with washer if needed)

On the stainless parts (head/body):

A2 / SS 304

Suitable for general indoor and outdoor industrial conditions

A4 / SS 316

Preferred for coastal, marine, poolside and many chemical atmospheres

Better resistance to pitting and chlorides

For harsh environments, A4 bi-metal CSK self-drillers are ideal.

Yes, but with care:

Deep countersinking in very thin sheet can make it weak and cause the head to knife through

For very thin sheet, consider:

A shallow/dimple countersink, or

Switching to pan head self-drilling screws

Always balance flush requirement vs sheet strength.

contact us

Partner with us for precision, quality, and reliability. Reach out and let's start building together.